Facilities

The Petroleum lab includes pilot-plant scale equipment that represents unit operations found in industrial settings. This includes an ebulliometer and distillation (both plate and packed columns), gas liquid absorption, and liquid-liquid extraction. This facility is specifically designed to introduce students to larger scale industrial processes commonly encountered by chemical engineers.

At the same time, the petroleum lab offers the students a unique learning experience with its equipment for testing and studying the properties of petroleum products (diesel, fuel, gas oil, kerosene, gasoline, bitumen, crude oil, LPG etc…). In the future, this lab could also offer commercial testing services to companies and industries.

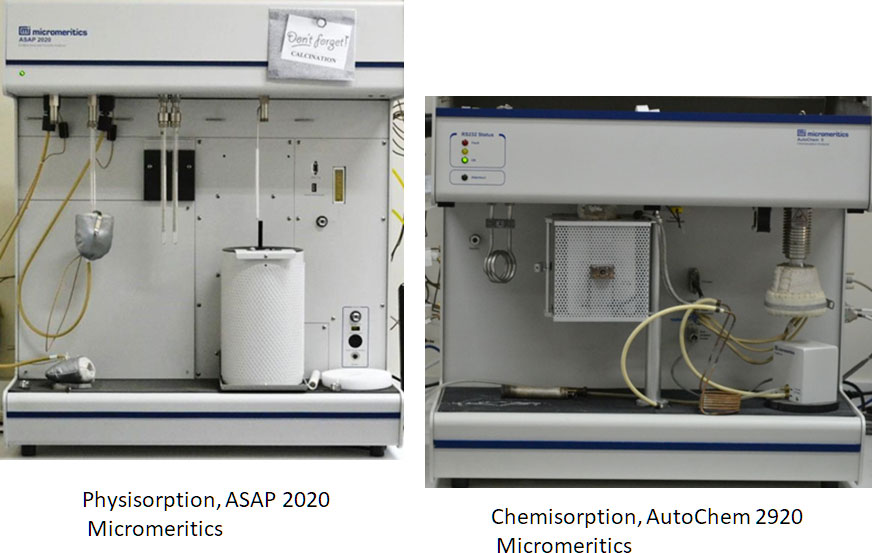

The Nanotechnology Laboratory is designed to serve graduate students. The following experiments can be performed:

Physisorption and Chemisorption using the ASAP 2020 (Micromeritics) for determination of: surface area, pore volume, pore size distribution and metallic dispersion.

Chemisorption using the AutoChem 2920 (Micromeritics) can determine percent of metal dispersion, active metal surface area, surface acidity, BET surface area. Some other experiments can be performed such as temperature-programmed reduction (TPR), desorption (TPD), oxidation (TPO). The exhaust gases can be analyzed by an on-line Mass spectrometer.

Gas pycnometer (Accupyc II 1340, Micromeritics) for the measurement of density of catalysts.

Microreactor (PID, Eng and Tech) for testing of the activity of catalysts in gas phase; the gases are analyzed on-line by a Micro-GC.

In the Corrosion Laboratory, labware and glassware for synthesis of catalysts (support synthesis, impregnation, calcination, etc) are available. For example oven, muffle furnace, large scale reactor, etc.

This lab also serves to perform experiments for the production of biodiesel

The Food Technology Lab covers the following equipment:

A Pasteurization unit, enabling the study of the heat exchanges in pasteurization for different residence times in the pasteurization chamber, or the pasteurization of orange juice and milk.

A Food Filter Press, allowing the study of the cake filtration process, either with a mixture of water and yeast, or a mixture of orange juice pulp and water.

A Temperature controlled room for the storage of food products.

The Unit Operations Lab provides students a practical industrial experience on the following units:

- • A Polyvalent Reactor for separation, dilution, purification, and chemical synthesis.

- • An Evaporation-Crystallization unit for the study of crystallization processes.

- • A set of Continuous Reactors for studying reaction conversion and residence time distribution.

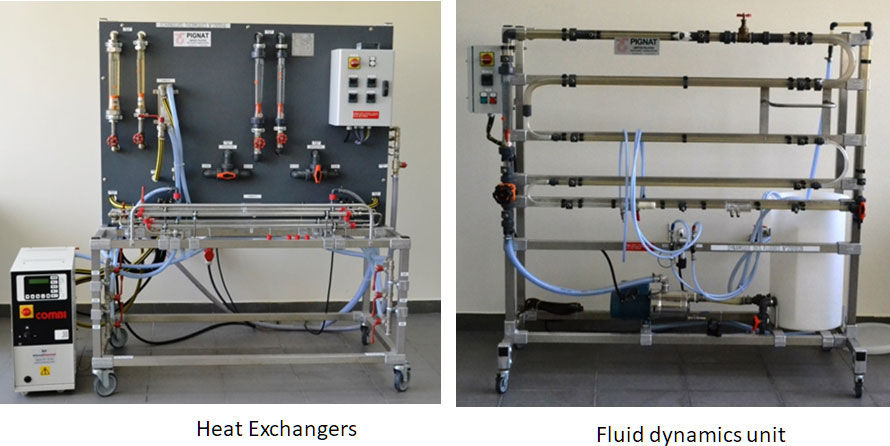

The Fluid Mechanics Lab includes the following advanced equipment:

A fluid dynamics unit for measuring the pressure drop across different flow configurations.

A centrifugal pumps unit for studying the efficiency of different types of pumps in single or in series/parallel modes.

A heat exchanger unit for studying conduction and convection heat transfer using single, shell-and-tube and plate heat exchangers for laminar and turbulent flow.

The Chemical Reactions Lab is a research facility highly equipped with the latest apparatuses among which:

X-ray Diffraction (XRD) allows the characterization of crystalline materials.

Effi Twin / Duo Reactor, connected to a four channel micro GC, operates on a micro-scale and is used for industrial catalyst and process design. It allows measuring the activity, selectivity, and stability of catalysts. Gas phase reactions can be studied in two independent reactors connected in series or in parallel.

Multi Bowl Spheronizer and Mini Screw Extruder are used for shaping of catalysts from powder to extrudates and spheres.

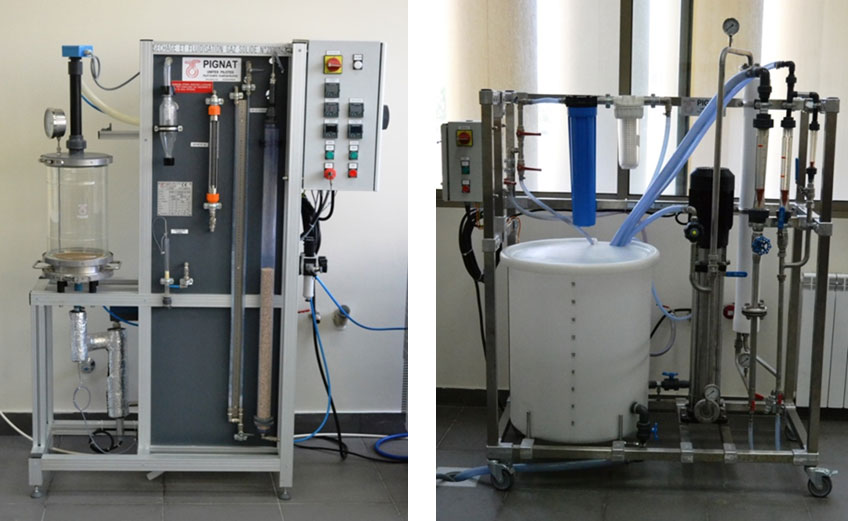

The transport phenomena lab provides students with a hands-on industrial experience on the following units:

A gas-solid fluidization and drying unit for studying the fluidization stages and the drying of alumina solid particles using hot air.

A reverse osmosis unit for measuring the osmotic pressure for municipal water and various saline solutions, as well as for studying the effect of the transmembrane pressure on the permeate quality and quantity.

A Pressurized Liquid Extraction system/Concentrator used for research purposes. It allows the extraction of organic compounds from solid matrices. The combined evaporator is used to concentrate the extracts obtained before analysis.

The Drilling Engineering Lab includes the most advanced drilling simulator that utilize a computer-based drilling operations management simulator to drill a well in a virtual environment.

It will provide virtual-on-the-job-training, by recreating the rigsite setup of the driller’s station, the drilling supervisor's station, and mud engineer's station.

During the class, the instructor will act in a mentor role, offering group skills training across a wide spectrum of drilling activities within the simulated operational scenario.